Beam cutting machine proCUT 6005

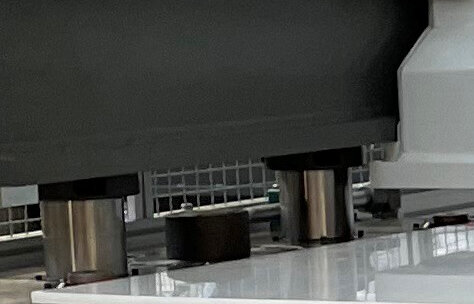

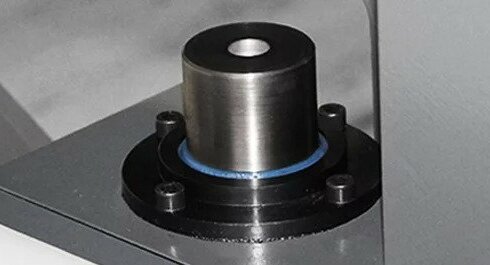

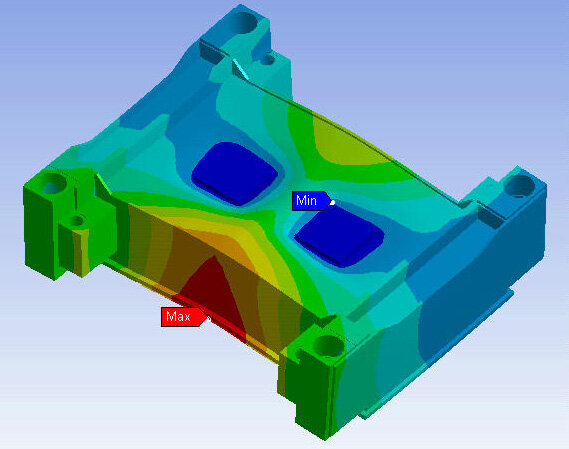

Universal cutting machine in a steel welded construction with Receding Beam

| Table size | 2060 mm x 1050 mm | 2060 mm x 1250 mm | 2060 mm x 1250 mm |

| Cutting force | 1250 kN | 1250 kN | 1600 kN |

| Daylight in mm (more possible) |

185 |

| Adj. return stroke in mm | 15 - 160 |

| Type | 6005/ 206.105/125 |

6005/ 206.125/125 |

6005/ 206.125/160 |

| Cutting in kN | 1250 | 1250 | 1600 |

| Cutting area in mm | 2060 x 1050 | 2060 x 1050 | 2060 x 1050 |

| Machine weight in kg | 10.000 | 10.500 | 15.000 |

| Oilrequirement in L. | 250 | 250 | 250 |

Product datasheet

Product datasheet